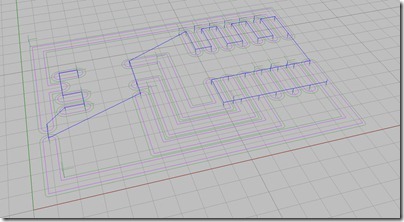

“Hand” drawn PCB in Rhino with toolpaths done in MadCam.

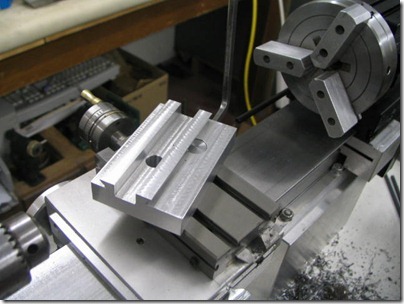

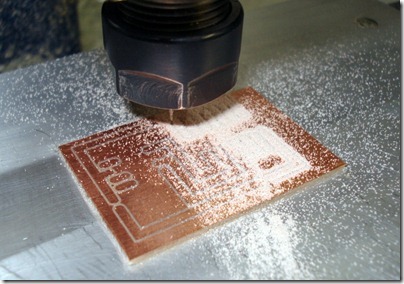

Milling with a .020” carbide end mill.

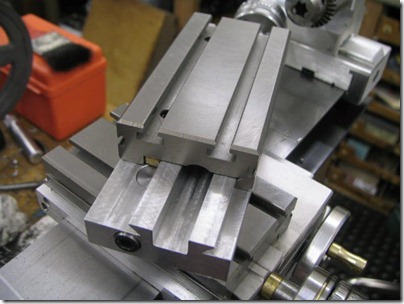

Another shot.

Very clean, no burrs.

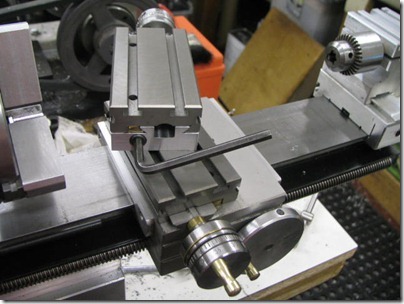

Holes drilled with a #59 carbide circuit board drill.

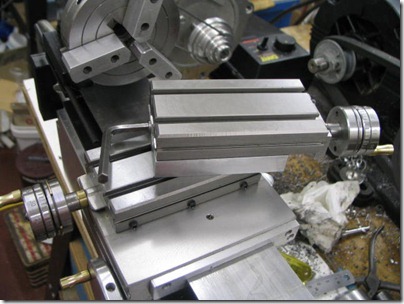

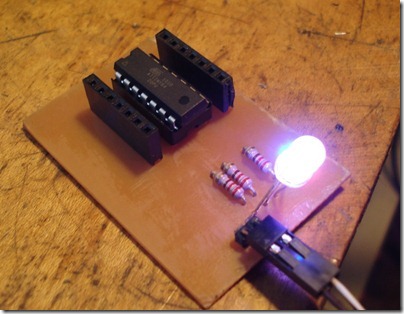

Soldered up and working. It’s an Attiny84 microprocessor driving an RGB LED with PWM so I can get a lovely mix of colors. The headers on either side of the chip are for reprogramming and additional utility. I'm using an Arduino to program the Attiny84.