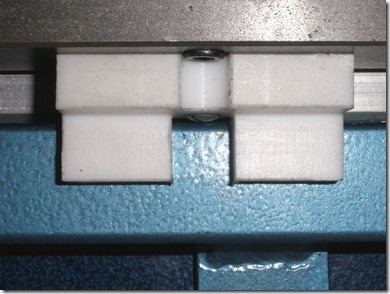

“Here's some pics of the setup and the limit switch arrangement with no holes drilled in the mill. The white things are the trippers and the run close to the brackets that hold the micro switches.”

Here are the pics of the mill limit switch brackets before being installed. #'s 1, 2, 3 are the X axis that mounts on using the holes for the rubber way protector. It mounts using the two end holes with access holes thru the top for an allen wrench. The rubber is sandwiched in between. The slot is 3/8" by 1/2" and the relief for the post is 3/8". Material is 1 3/4" x 1 3/4" x 6 1/2". I used .080" but it's a little too thick and makes it hard to get the trip levers to actuate the micro switches.

“Z, made from 1" x 2" x 7 1/2" x .058". It is mounted using the holes tapped in the vertical axis post that mounts the power switch. Compression posts made of tubing sleeve the holes. Holes on the part next to the post are clearanced for the screw and the ones on the outside are just big enough for the tubes to pass and finish up flush.”

“the Y axis, made of 1" x 1" x 8" x .058" with two brackets. The brackets are 2" tall with a 1 5/8" foot, 1" x 1 1/2"

wide. The micro switches are approximately 1" x 3/4" x 1/2" and are mounted with 4-40 countersunk screw so the moving parts clear. The trip devices are made of a Teflon like material machined to ride on the moving component just off the surface of the brackets and tripping the actuator lever of the micro switch. It may be necessary to add a piece of shim stock to the lever to make them work, I used .030, glued to the lever with epoxy. “

Here are the pics of the microswitch trip pieces for the mill. The Z is a simple angle piece with a small ramp cut at the top so it can allow the Z axis to go to the limit. X was made as one piece, then cut in half. Drilled the holes first then milled away the sides to leave a ridge. The ridge centers the part and prevents the screws from marring the groove in the table. Cut the 4-40 allen screws to length so they don't bottom against the back of the nut retainer slot in the table. The Y is a piece of work and difficult to get off as it is necessary to remove the microswitch bracket first. The drawing that is enclosed with the copy's I sent you is probably more understandable that what I can write. It's a goofy design but the best I could come up with at the time. All the material I sent you is just meant to be an idea and not an exact blueprint. Everyone should make their own measurements. The main theme was to not drill any holes in the machine, just use the existing ones.

No comments:

Post a Comment